How to Make a Medical Seal: A Comprehensive Guide

Medical seals, often called doctor stamps, serve as an official mark of authenticity on prescriptions, clinical records, and laboratory orders while reinforcing patient confidence in healthcare documentation. By replacing handwritten signatures, these seals not only standardize documents but also accelerate administrative workflows across medical practices.

Why Seals Matter

Medical seals provide a rapid visual cue that a document is legitimate and comply with regulatory frameworks, reducing fraud and misinterpretation in clinical settings.

They also streamline daily routines by allowing healthcare providers to imprint necessary credentials in one action, rather than repeatedly signing each paper by hand.

Regulatory Requirements

Healthcare authorities universally require seals to display the practitioner’s full name in the nominative case and their official specialization, or simply “Doctor” if unspecified.

A consistent circular shape—typically between 20 mm and 40 mm in diameter—ensures clarity when stamped on various paper stocks and electronic scans.

Certain jurisdictions may mandate inclusion of a professional license number or institutional logo to further validate the seal’s authenticity.

Design Principles

- Font choice should prioritize readability; serif or clean sans-serif faces in 8–12 pt sizes strike the right balance between formality and legibility.

- Dual-ring borders help define the seal’s boundary without cluttering internal text, framing the name and title clearly.

- Medical symbols—such as the Rod of Asclepius—can be centered or offset, provided they do not overlap core text elements.

- High-contrast ink (black or deep blue) maximizes visibility on both printed and scanned documents.

Material Selection

Medical seals are commonly manufactured from photopolymer or hard rubber, each offering distinct advantages in resolution and longevity.

Self-inking mechanisms house an integrated ink reservoir for thousands of impressions, reducing the need for frequent re-inking and maintaining stamp clarity over extended use.

Choosing between polymer and rubber hinges on desired impression crispness, expected usage volume, and per-unit cost considerations.

Manufacturing Techniques

Laser engraving produces exceptionally sharp edges in hard rubber seals, ideal for fine text and intricate logos.

Photopolymer seals cure rapidly under UV light, delivering high-detail impressions suitable for multi-line stamps with minimal lead time.

For high-volume clinical environments, self-inking housings minimize user effort and prevent ink pooling or smudging on documents.

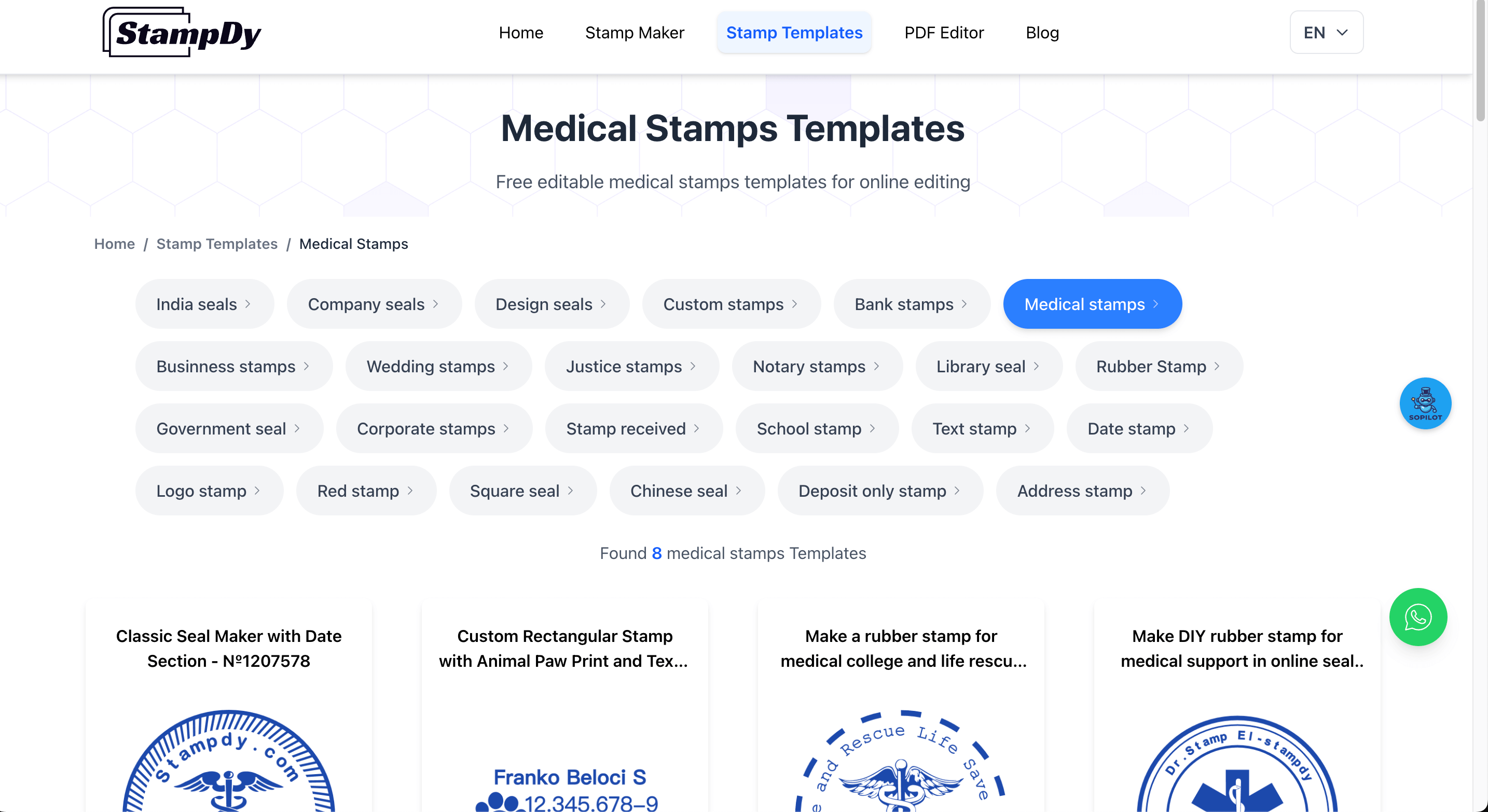

Online Seal Makers

Online platforms allow users to create a custom medical seal without design software.

After selecting a “Medical Seal” template, input fields guide entry of name, title, license number, and optional logo in real time.

Interactive controls adjust diameter, font weight, and border thickness, with a live preview ensuring compliance and aesthetic balance before download.

Customization Tips

Limit extraneous graphics: a small institutional logo may be used sparingly, but avoid any element that infringes upon mandatory text clarity.

Consider embedding a QR code on specialty or marketing seals to link digital credentials or patient feedback forms—while preserving a separate official seal for regulatory documents.

Refrain from color accents on legally binding documents; stick to monochrome for consistent legibility across varied lighting and scanning conditions.

Quality Assurance

Conduct test impressions on multiple paper types—glossy, matte, and recycled—to verify ink adhesion and text sharpness under real-world conditions.

For photopolymer seals, track impression counts and replace the seal after the manufacturer’s specified threshold to prevent fading or incomplete text.

If seals are used near sterile fields, ensure materials meet biocompatibility standards to avoid contamination risks.

Maintenance and Storage

Refill self-inking seals with manufacturer-approved ink cartridges to maintain consistent color density and prevent chemical degradation.

Store stamps upright in a cool, dry environment to preserve rubber elasticity and prevent warping of polymer plates.

Clean seal surfaces periodically with isopropyl alcohol and a soft cloth to remove accumulated debris without damaging engraved details.

Global Regulatory Comparison

Regulations for medical seals vary across regions but share core principles of authenticity and legibility.

In the United States, seals are governed by state medical boards, which may require unique identifiers such as DEA numbers or state license expiration dates.

European Union members adhere to national health authority guidelines that align with EU directives, often mandating CE markings on device seals for intra-EU recognition.

In India and many Asian countries, seals must reference national medical council registrations, while Latin American jurisdictions sometimes require bilingual text to accommodate local languages.

Historical Evolution of Medical Seals

The use of physician stamps dates back to medieval guilds, where practitioners marked official documents to certify treatments.

During the 19th century, rubber stamping technology enabled mass production of personalized seals, revolutionizing administrative efficiency in hospitals.

The digital era introduced electronic seals, allowing virtual documents to bear cryptographic marks that verify the origin and integrity of digital prescriptions and reports.

Case Studies and Use Cases

At a busy cardiology clinic, adopting self-inking photopolymer seals reduced appointment check-in times by 20%, as staff no longer paused to retrieve signature logs.

A telemedicine provider integrated electronic seals into patient portals, enabling remote physicians to authenticate digital prescriptions securely and reducing mail-time delays.

A rural health outreach program employed custom QR-embedded seals to link patients’ stamped referrals directly to online appointment booking systems, improving care coordination.

Choosing a Vendor

When evaluating seal manufacturers, consider minimum order quantities and turnaround times.

Review material warranties: some vendors offer lifetime guarantees on rubber seals, while polymer plates may have limited impression counts.

Assess template libraries and customization interfaces—robust online design tools can save hours compared to manual layout reviews.

Cost Considerations

Entry-level rubber seals typically range from $15 to $30 per unit, with bulk discounts available for orders over 50 stamps.

Photopolymer seals cost slightly more upfront (around $25 to $40), but rapid production and high resolution justify the investment for multi-line or logo-heavy designs.

Self-inking models begin at $35, with premium metal-cased versions reaching $70, offering superior longevity and ink capacity for high-throughput clinics.

Digital Seals and Electronic Signatures

Electronic seals combine digital certificates with cryptographic hashing to authenticate documents in PDF or EHR systems.

Software solutions integrate seal creation into practice management platforms, automating seal application with user-specific credentials.

Regulatory bodies increasingly accept e-seals for telehealth and remote prescribing, provided they meet digital signature standards such as eIDAS in Europe or UETA in the US.

Integrating Seals into Practice Workflows

Train staff on seal usage best practices, including impression pressure and stamp orientation to maintain consistency.

Incorporate seal application checkpoints into electronic medical record templates, prompting users to select the correct seal type before finalizing documents.

Monitor seal usage analytics—digital systems can log each seal application event, helping administrators track frequency and detect anomalies.

Future Trends

3D-printed stamp plates are emerging, enabling ultra-rapid prototyping of custom seal designs at point of care.

Biometric-linked digital seals are under development to tie electronic stamps to individual user fingerprints or iris scans, enhancing non-repudiation.

Sustainable materials—such as biodegradable polymers—are gaining traction for eco-friendly seal production in green healthcare initiatives.

Frequently Asked Questions

- What diameter is best for a seal when space is limited?

A 25 mm seal strikes a balance between legibility and compactness, fitting neatly in prescription headers without overwhelming the layout. - Can I reuse a photopolymer plate if my details change?

Photopolymer plates are single-use once etched; order a new plate or choose modular rubber inserts for easy text updates. - Are electronic seals legally binding?

Yes, when they comply with jurisdictional e-signature regulations such as UETA, ESIGN, or eIDAS, they carry the same legal weight as wet-ink seals. - How often should I replace my self-inking seal?

Most manufacturers recommend a cartridge change after 2,000 impressions or six months of active use to maintain optimal ink flow.

Conclusion

By integrating clear regulatory guidance, thoughtful design, and durable materials, medical professionals can rapidly create compliant and personalized seals that enhance both efficiency and document security. Leveraging online tools and embracing digital seal technology further simplifies the process, empowering practitioners to produce high-quality seals within minutes and focus attention on patient care rather than paperwork. Continuous advancements in materials and digital integration promise a future where medical seals are as dynamic and interconnected as the healthcare systems they serve.